Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Putzmeister

Putzmeister

(20)Concrete Pump Outer Housing

The outer housing of a concrete pump is the protective casing that encloses the internal components of the pump. It is made from high-strength steel or aluminum and is designed to withstand the rigors of concrete pumping operations, including heavy use, exposure to harsh environments, and impacts from debris. It also feature access doors or panels that allow for easy maintenance and servicing of the internal components.

Concrete Pump Reducer

A concrete pump reducer is used to connect pipes of different diameters together and is typically made of high-strength steel. The reducer plays a crucial role in ensuring that the concrete flows smoothly and quickly through the pump, reducing the risk of blockages and ensuring that the concrete is delivered where it is needed.

Concrete Pump Cutting Ring For Putzmeister

The wear ring, also known as the cutting ring, is a vital component of a concrete pump. The cutting ring forcefully brushes against the concrete, cutting stones while enduring significant friction force. Due to this, the cutting ring is one of the components on the concrete pump that experiences the most wear and tear. It can withstand the constant friction force to ensure the efficient and safe operation of the machinery.

Concrete Pump Fission Piston

Looking for high-quality Concrete Pump Fission Pistons? Look no further than CANGZHOU HAOLONG CONSTRUCTION MACHINERY CO., LTD! With years of experience in producing fission pistons, we offer a wide variety of options to meet your specific needs. Whether you need a standard size or a customized solution, we can provide prompt assistance online.

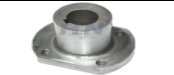

Concrete Pump Bearing Flange

We take pride in offering the best and highest quality selection of bearing support flanges in our concrete pump bearing flange product line. We ensure that our product meets established quality standards, providing our customers with a reliable and durable solution for their concrete pumping needs. Our concrete pump bearing flange is available at an affordable price, making it accessible to a wide range of customers.

Concrete Pump Battery

A concrete pump battery is specially designed to provide power to hydraulic pumps and other components of concrete pumps. It is designed to be durable, maintenance-free, and capable of deep discharge and recharge cycles. Concrete pump batteries are a critical component in the efficient operation of concrete pumps, delivering reliable power for continuous use on construction sites.

Concrete Pump Charger

We offer a single type of Putzmeister concrete pump battery charger that is compatible with the remote control for worn components. Our chargers come in black and blue and can provide 26V and 30V batteries. If you are interested in our concrete pump chargers, please do not hesitate to contact with us!

Concrete Pump Conveying Cylinder

A Concrete Pump Conveying Cylinder is responsible for pushing the concrete from the hopper into the delivery pipeline. It is made of high-strength steel and has a piston that moves back and forth inside the cylinder to pump the concrete. The Conveying Cylinder ensures a smooth and consistent flow of concrete while avoiding blockages and other issues that may compromise the efficiency and safety of the pumping operation.

Concrete Pump Ball Socket

These spherical-shaped parts act as bearing joints, providing a ball-and-socket joint that is structurally sound. The socket must be made with extreme precision to fit the sphere on the piston rod, ensuring a secure and stable connection. The materials used are durable and able to withstand the heavy use and pressure of the pumping operation.

Concrete Pump Plunger Cylinder

A concrete pump plunger cylinder is a hydraulic actuator that converts hydraulic energy into mechanical energy, creating a swinging motion. It is a vital component of a concrete pump and has a simple design and reliable operation. With our extensive industry experience and expertise, we offer an excellent range of concrete pump plunger cylinders.

Concrete Pump S-Valve

The S-valve is a crucial component of any concrete pumping system. It works in tandem with the wear plate to transfer concrete from the pumping cylinders to the discharge conduit. The valve is located inside the concrete hopper and can be rotated to connect one of the two pumping cylinder outlet ends to the input end of the discharge conduit, which is located on the hopper’s front wall.

Concrete Pump Mixer Shaft For Putzmeister

We are a top producer and supplier of Concrete Pump Mixer Shaft for Putzmeister. Our skilled employees use state-of-the-art equipment to create a high-quality surface finish. This mechanical tool is made of alloyed steel, providing exceptional strength, rigidity, and resistance to moisture and chemicals, preventing corrosion. You can purchase this premium product in bulk from us at a competitive price.